DRDO’s LFRJ Engine DcPP: 14 Indian Firms Vie for Supersonic Missile Propulsion Supremacy

In a pivotal move to advance India’s indigenous missile capabilities, the Defence Research and Development Organisation (DRDO) has initiated a competitive Development-cum-Production Partner (DcPP) program for its Liquid Fuel Ramjet (LFRJ) engine. This cutting-edge propulsion system is set to power the next generation of supersonic cruise missiles, enhancing range, speed, and operational efficiency. With 14 prominent Indian vendors entering the fray, this initiative underscores the growing collaboration between DRDO and the private sector, aligning with the Atmanirbhar Bharat vision of self-reliance in defence technology. The program, announced via a Request for Information (RFI) in September 2025, has generated significant buzz in the defence industry, as it promises to revolutionize India’s aerial strike capabilities amid escalating regional security challenges.

Understanding the LFRJ Engine: Technical Specifications and Innovations

The Liquid Fuel Ramjet (LFRJ) engine represents a sophisticated advancement in air-breathing propulsion technology. Unlike traditional solid-fuel rockets, ramjets compress incoming air using the vehicle’s forward motion, eliminating the need for heavy compressors and making them ideal for high-speed applications. The LFRJ variant employs liquid fuel, offering greater control over thrust and efficiency compared to solid-fuel counterparts. Key technical specifications include:

- Diameter and Design: The engine features a 350mm diameter, optimized for integration into medium-sized missiles. Its design incorporates an intake system that efficiently captures and compresses supersonic airflow, enabling sustained high-speed flight.

- Thrust and Performance: Capable of generating thrust in the range of 5-10 kN, the LFRJ allows missiles to achieve speeds of Mach 2 to Mach 3 (approximately 2,400-3,700 km/h). This is facilitated by a two-stage propulsion: an initial solid booster for launch and acceleration, followed by the ramjet sustainer for extended cruise.

- Fuel Efficiency and Range: Liquid fuels like kerosene-based mixtures provide superior energy density and throttleability, extending missile ranges to 55-175 km or more, depending on the variant. This efficiency is crucial for applications where endurance outweighs raw acceleration.

- Sensor Integration: Embedded digital sensors monitor critical parameters such as airflow, pressure, temperature, and combustion uniformity in real-time. This data feeds into an onboard control system, ensuring stable operation even under varying atmospheric conditions.

- Hypersonic Integration Potential: While primarily for supersonic regimes, the LFRJ’s design draws from DRDO’s scramjet research, paving the way for hybrid systems that could transition to hypersonic speeds (Mach 5+). Recent ground tests of related scramjet combustors, exceeding 1,000 seconds of operation, highlight this evolutionary path.

Developed primarily by DRDO’s Defence Research and Development Laboratory (DRDL) in Hyderabad, the LFRJ builds on successes like the Solid Fuel Ducted Ramjet (SFDR) tested in 2021. Innovations in fuel formulation, such as specialized cooling agents developed with local firms, address thermal management challenges, preventing engine overheating during prolonged high-speed flights. This technology not only boosts missile performance but also reduces logistical burdens, as liquid fuels are easier to store and handle than solids.

Profiles of Top Contenders: The 14 Vendors in the Spotlight

The DcPP program has attracted a diverse array of Indian defence and aerospace firms, blending established giants with innovative players. These vendors will compete to become DRDO’s partner in developing, testing, and producing the LFRJ engine. Here’s a closer look at the 14 contenders, showcasing India’s robust industrial ecosystem:

- Godrej & Boyce (Mumbai): Renowned for precision engineering, Godrej has supplied components for BrahMos and Agni missiles, bringing expertise in rocket motor casings and propulsion systems.

- Larsen & Toubro (L&T) Defence: A heavyweight in engineering, L&T has experience in submarine and missile manufacturing, positioning it well for large-scale production.

- Tata Advanced Systems Limited (TASL): Tata’s defence arm excels in aerospace integrations, with prior collaborations on UAVs and missile subsystems.

- Bharat Dynamics Limited (BDL): As a public sector undertaking, BDL specializes in missile production, including Akash and Prithvi, offering seamless integration know-how.

- MTAR Technologies: Experts in precision machining, MTAR has contributed to ISRO’s engines and DRDO’s hypersonic projects.

- VEM Technologies: Focused on electronics and seekers, VEM brings sensor and control system expertise to the table.

- Bharat Forge: Known for forging and artillery, it has ventured into aerospace with advanced material capabilities.

- Kalyani Strategic Systems: Part of the Kalyani Group, it specializes in defence metallurgy and propulsion components.

- Alpha Design Technologies: Leaders in avionics and simulation, enhancing the engine’s digital monitoring features.

- Data Patterns: Provides radar and electronic warfare systems, aiding in sensor fusion.

- Astra Microwave Products: Experts in RF and microwave components, crucial for missile guidance.

- Zen Technologies: Innovators in training simulators, potentially contributing to engine testing protocols.

- Solar Industries: Specialists in explosives and propellants, supporting fuel development.

- Premier Explosives: Focused on high-energy materials, essential for booster stages.

These firms were shortlisted based on their technical capabilities, financial stability, and track record in defence projects. The selection process involves rigorous evaluations, including prototype demonstrations and cost assessments, ensuring the chosen partner can scale production for military needs.

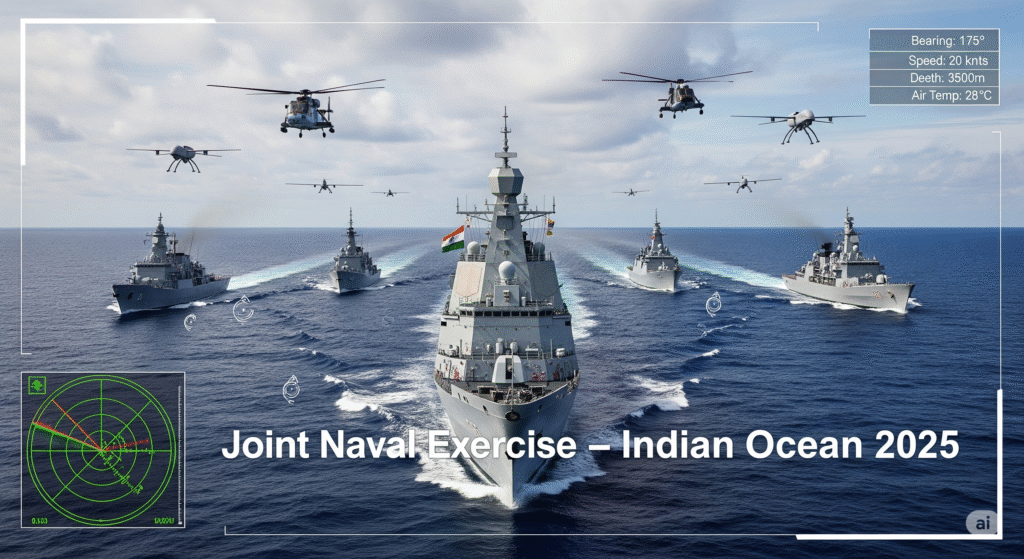

Strategic Edge: Bolstering Indigenous Missile Tech Amid Regional Threats

The LFRJ engine’s development is strategically vital for India, especially in the context of regional tensions in the Indo-Pacific. With neighbors like China advancing hypersonic weapons, India seeks to close the gap through indigenous innovations. The engine will power missiles such as the Supersonic TARget (STAR), designed for anti-AWACS, anti-radiation, and target simulation roles. Launched from platforms like the LCA Tejas, STAR can operate at altitudes from 0.1 to 10 km, providing versatile strike options.

By indigenizing propulsion, India reduces dependency on imports, mitigates supply chain vulnerabilities, and fosters economic growth. The DcPP model encourages private investment in R&D, potentially creating thousands of jobs and boosting exports. Analysts predict that successful LFRJ integration could extend BrahMos-like missiles’ ranges, enhancing deterrence against asymmetric threats. Moreover, this aligns with global trends toward air-breathing engines, positioning India as a key player in advanced defence tech.

Timeline for Trials and Induction: Road to 2028

The program’s timeline is ambitious yet structured. Following the RFI in September 2025, DRDO aims to issue a Request for Proposal (RFP) by early 2026, with vendor selection by mid-2026. Ground testing of prototypes is slated for late 2026, followed by flight trials in 2027. Full induction into service is targeted for 2028, coinciding with upgrades to existing missile fleets.

Challenges include mastering combustion stability and material durability under extreme conditions, but DRDO’s prior scramjet successes—such as the 1,000-second combustor test in April 2025—provide a strong foundation. Collaborations with academic institutions and international benchmarks will accelerate progress.

Accelerating Scramjet Evolution and Future Prospects

The LFRJ program is a stepping stone to scramjet technologies, where air flows supersonically through the engine. By refining ramjet basics, DRDO is laying groundwork for hypersonic missiles capable of Mach 6-8 speeds. This evolution could transform India’s defence arsenal, enabling rapid, evasive strikes that outpace adversaries’ defences.

In conclusion, the DcPP race for the LFRJ engine exemplifies India’s commitment to technological sovereignty. As these 14 firms compete, the outcome will not only propel missiles but also India’s global standing in defence innovation. With regional stability at stake, this initiative is a testament to strategic foresight and industrial synergy.