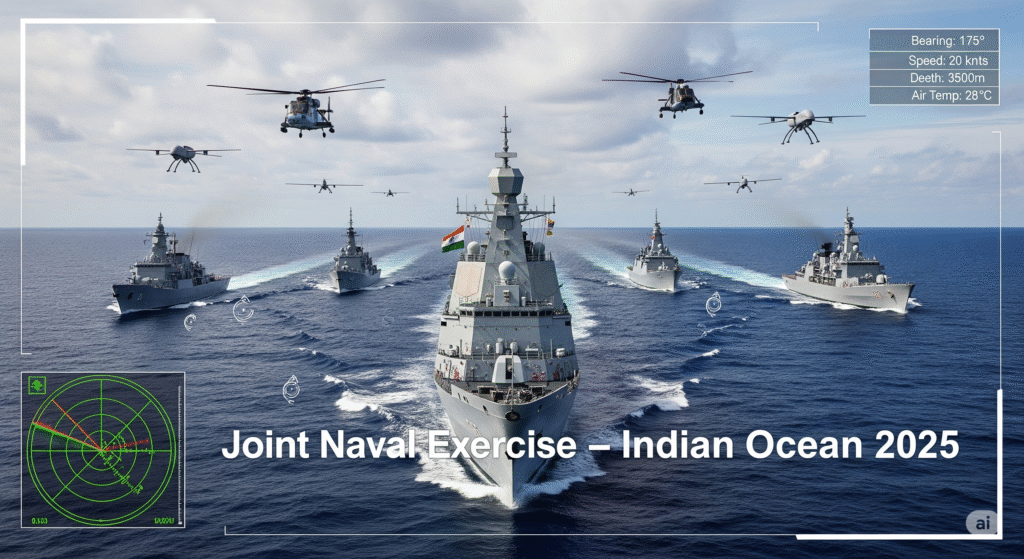

Is ‘Make in India’ Delivering Faster Results Than Imports in Defence? A 2025 Evidence-Based Review

The transformation of India’s defence sector in the past five years has raised a critical question: Is the “Make in India” model actually enabling faster, better and more resilient military modernization compared to legacy import-driven procurement? In 2025, as new platforms, local startups, and government reforms surge, it’s time to weigh the evidence—cutting through the rhetoric to assess what’s working, what needs fixing, and where India’s future truly lies.

Quantitative Gains: Speed, Scale & Induction

- Indigenous platforms: 65% of net asset additions in 2022–25, up from 40% prior period

- Tejas Mk-1A jets: 18 inducted in 24 months, beating import timelines

- Akash NG & Pinaka: 500+ units delivered in 2 years, rapid maintenance/upgrades

- BrahMos NG: Fast integration, no Russian module delays

Quality, Customization, and Upgrade Cycles

- Customization for Operations: Rapid field feedback and upgrades

- Shorter Supply Lines: Spares/logistics delivered locally in weeks not months

- MoD Oversight: Flexible technical reviews, DAP reforms

What’s Slower or Still Lagging?

- Complex systems (jet engines, radars, heavy lift): Indigenous development slower than imports

- Certification and export competitiveness: Indigenous platforms catching up

- MSME scale-up: Pilot to full induction can be slower unless accelerated

Case Studies: Successes and Shortfalls

- LCA Tejas: Import logjam broken, upgrades every 18 months

- Arjun Mk-1A: Obsolescence slashed, exports in discussion

- INS Vikrant: Longer build, faster upgrades/maintenance than imports

- Infantry: Local carbines and night-vision now catching up to imports

Policymaker & Expert Voices

- MoD 2025 White Paper: Major indigenous platforms inducted <3 years vs. 4.5+ for imports

- MSME perspective: Faster repairs/upgrades than legacy supply chains

- Army/Air Force feedback: Indigenous suppliers—rapid product tweaks, better readiness

Fixing the Gaps: Suggestions from 2025

- Global benchmarking for certification and exports

- Accelerator scale-up (iDEX/ADITI)

- Strategic partnerships for selective imports and better ToT

- Talent pooling for prototype-to-battlefield transition

Outlook: The Path Forward

“Make in India” is now essential for sovereignty, speed, and sustainable capacity. Select imports remain critical, but the mix leads India’s modernization toward self-reliance—including platforms, upgrades, and innovation.

Conclusion: India’s Defence Modernization—Best When Built at Home

To be “future-ready”, India’s defence industry must keep scaling its local ecosystem, investing in joint research, and sharpening adoption cycles. Speed, resilience, and technological control will define victory—make in India is not just a slogan, but a proven strategy as of 2025.